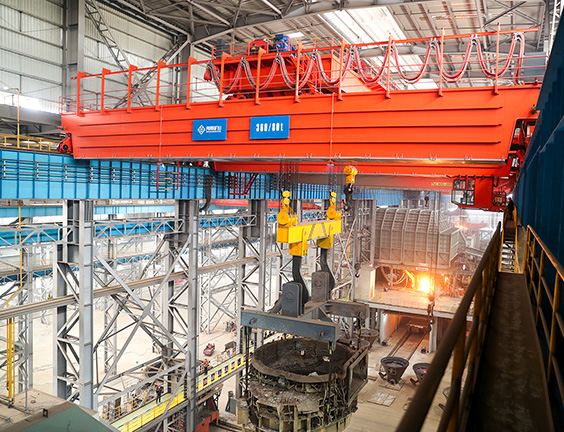

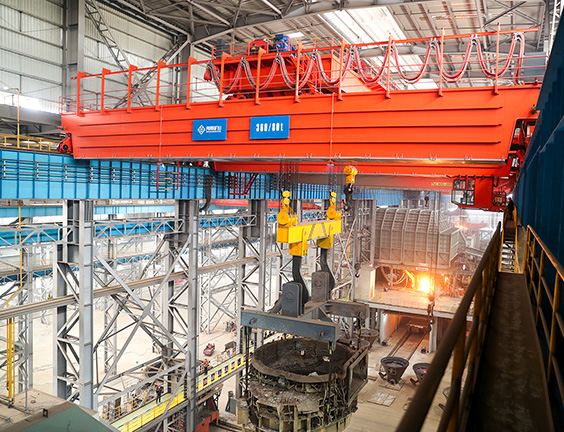

The ladle crane is the main lifting and transportation equipment in the smelting workshop of the steel plant. It is used to transfer, pour and mix liquid metal during the smelting process. The ladle crane weighing below 125t usually adopts a YZ type double-beam structure. The ladle crane weighing above 125t usually adopts a YZS type four-beam structure. The YZS type adopts main and auxiliary trolleys, four beams and four tracks. It is mainly composed of a bridge frame, a main trolley, an auxiliary trolley, a hook beam, a cart traveling mechanism and electrical parts. The main trolley runs on the main beam track outside the bridge frame, while the auxiliary trolley runs on the auxiliary beam track inside the bridge frame. The main trolley's load-handling device is the hook beam with a fixed spacing.

The ladle crane is the main lifting and transportation equipment in the smelting workshop of the steel plant. It is used to transfer, pour and mix liquid metal during the smelting process. The ladle crane weighing below 125t usually adopts a YZ type double-beam structure. The ladle crane weighing above 125t usually adopts a YZS type four-beam structure.

The YZS type adopts main and auxiliary trolleys, four beams and four tracks. It is mainly composed of a bridge frame, a main trolley, an auxiliary trolley, a hook beam, a cart traveling mechanism and electrical parts. The main trolley runs on the main beam track outside the bridge frame, while the auxiliary trolley runs on the auxiliary beam track inside the bridge frame. The main trolley's load-handling device is the hook beam with a fixed spacing, which is used to lift steel ladles. The auxiliary trolley runs under the main trolley, whose load-handling device is a hook, which is used to cooperate with the main hook in dumping molten steel and steel slag and other auxiliary lifting operations.

The YZ type adopts a double-beam single-trolley structure, which is mainly composed of a bridge frame, a trolley, a hook beam, a cart traveling mechanism and electrical parts. The load-handling device of the main hook is a fixed-spacing hook beam, which is used to lift steel ladles. The auxiliary hook is used to cooperate with the main hook in dumping molten steel and steel slag and other auxiliary lifting operations.

The cart traveling mechanism and main electrical devices are installed in the main beam, and an air cooler is installed in the main beam electrical room. To reduce the heat radiation of molten steel to metal structural parts, a heat insulation board is provided at the bottom of the main beam along the span direction.

The cart traveling mechanism adopts the four-corner drive mode.

The crane is equipped with a special electronic scale. Display devices are set in the cab and on the bridge frame.

Henan Kuangshan Crane Co., Ltd. (hereinafter referred to as "Henan Kuangshan") was founded in 2002 with a registered capital of 1.177 billion yuan and a built-up area of 1.62 million m2.